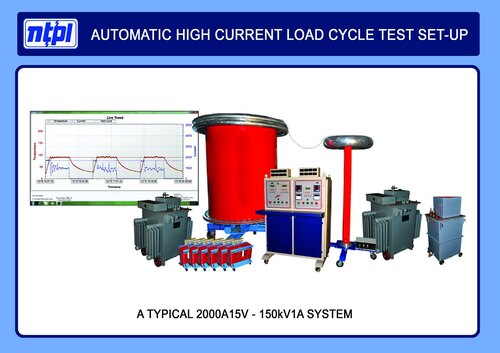

Load Cycle Test Set-Up

3545000 INR/Unit

Product Details:

- Resistant Feature Corrosion and high-temperature resistant

- Pressure Atmospheric

- Accuracy 1% FS

- Usage & Applications Testing electrical equipment and components under repetitive loading conditions

- Product Type Load Cycle Test Set-Up

- Material Mild Steel body with powder coated finish

- Measuring Voltage Range 0-300V AC / 0-500V AC (customizable)

- Click to view more

X

Load Cycle Test Set-Up Price And Quantity

- 3545000 INR/Unit

- 1 Unit

Load Cycle Test Set-Up Product Specifications

- Corrosion and high-temperature resistant

- Overload & short circuit protection

- Atmospheric

- Ambient to 150C

- 1% FS

- Load Cycle Test Set-Up

- Testing electrical equipment and components under repetitive loading conditions

- Approx. 1200 mm x 800 mm x 1800 mm

- Customizable

- Blue & White

- Approx. 250 kg

- 0-300V AC / 0-500V AC (customizable)

- Mild Steel body with powder coated finish

- Double wall insulated chamber

- 50 Hz

Load Cycle Test Set-Up Trade Information

- All India

Product Description

Technical Specification:

Subunits :The above test kit will be in multiple subunits i.e.

- Power Mains Control Panel with Air Circuit Breaker

- Control & Measurement Unit

- Voltage Regulator

- Power Compensating Reactor

- AC High Voltage Transformer

A brief technical account of the Automatic Low Voltage High Current Injection Set is specified as below.

Subunits :The above test kit will be in multiple subunits i.e.

- Microcontroller base Control & Measurement Unit

- Regulator Unit

- Current Loading Transformers

All the above units will be provided with wheels for easy movement.

Software :PC based Data Acquisition System is provided along with application software. This will enable the operator to control & monitor the system remotely. Operator can capture the Live Trends and view all the system parameters using the software.

Intuitive Control and Reliable Data Management

The touch screen control panel, equipped with a microcontroller interface and emergency stop, provides user-friendly operation and real-time monitoring. Easily export test data through the built-in USB port for documentation and analysis, ensuring precise and accountable results.

Engineered for Accuracy and Compliance

Adhering to IS 2026 and IEC 60076 standards, the system guarantees reliable and standardized test procedures. Its measurement range of 0-300V or 0-500V AC (customizable) and 1% FS accuracy make it suitable for a variety of electrical testing applications.

Advanced Protection and Safety Features

The test set-up includes overload, short circuit, and thermal cut-off protections, along with door interlocks and a robust insulated chamber. These features collectively safeguard users and test specimens while allowing continuous operation up to 500A.

FAQs of Load Cycle Test Set-Up:

Q: How does the Load Cycle Test Set-Up ensure accurate testing during repetitive loading?

A: The test set-up maintains accuracy through its microcontroller-based digital interface, which offers real-time monitoring and consistent control. Its measurement system, featuring a 1% FS accuracy, supports precise testing during each load cycle.Q: What types of data can be exported and how is data logging managed?

A: The digital display control panel allows users to export test data via the built-in USB port. This includes voltage, current, cycle count, and temperature measurements, making it easy to analyze and maintain comprehensive test records.Q: When should the emergency stop and safety interlocks be used?

A: The emergency stop should be activated immediately in the event of unsafe conditions or equipment malfunction. Door and thermal cut-off interlocks engage automatically when access panels are opened or excessive temperatures are detected, enhancing operator safety at all times.Q: Where is the cable entry located, and how does it affect installation?

A: Cables are routed through the rear side of the set-up using a gland plate, making installation straightforward and secure while minimizing cable strain and ensuring a tidy test environment.Q: What is the process for adjusting sample holding clamps during testing?

A: The stainless steel sample holding clamps are fully adjustable, allowing users to securely position various electrical components within the double-walled insulated chamber, optimizing contact and ensuring repeatable test results each time.Q: How does the automatic air ventilation system benefit long-term operation?

A: The automatic air ventilation system maintains safe operating temperatures by efficiently dissipating heat during extended or high-current tests, which helps preserve equipment life and maintain consistent test conditions.Q: What are the key benefits of using this test set-up for manufacturers and suppliers in India?

A: Manufacturers and suppliers benefit from its robust safety features, customizable configurations, data management capabilities, and compliance with relevant international standards. Its corrosion and high-temperature resistance ensure reliable operation in diverse industrial environments.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

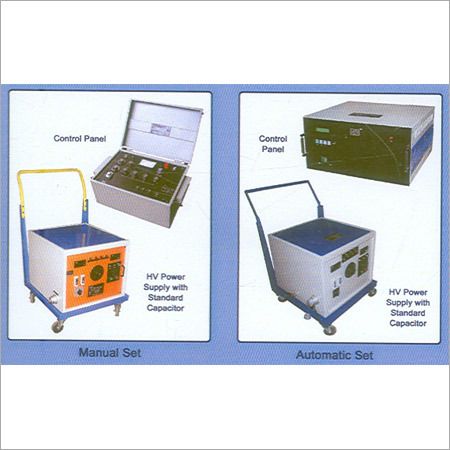

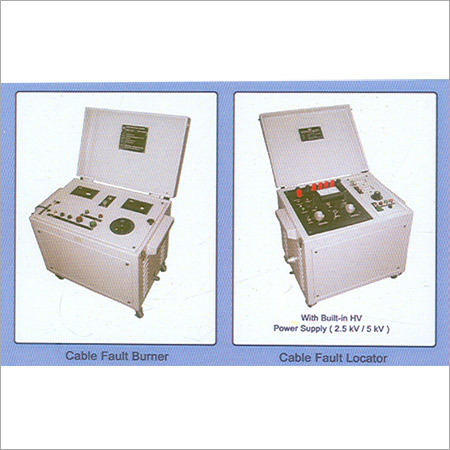

Other Products in 'Test Sets for Cable Industries' category

Works:

117, Mishrapara Road, Rathtala, P.O. Rajpur,

Kolkata - 700 149, West Bengal, India.

Call Me Free

Call Me Free