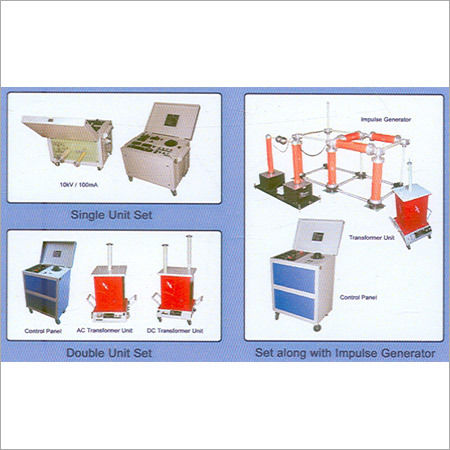

Partial Discharge Test Set Up

5000 MXN ($)/Unit

Product Details:

- Product Type Manual,Automatic,Motorised

- Frequency (MHz) 50-60 Hertz (HZ)

- Insulation Box NA

- Protection System NA

- Size NA

- Color NA

- Warranty 12months

- Click to view more

X

Partial Discharge Test Set Up Price And Quantity

- 1 Unit

- 5000 MXN ($)/Unit

Partial Discharge Test Set Up Product Specifications

- 12months

- NA

- NA

- 50-60 Hertz (HZ)

- NA

- Manual,Automatic,Motorised

- NA

Partial Discharge Test Set Up Trade Information

- kolkata

- 50 Unit Per Month

- 7-15 Days

- Sample costs shipping and taxes has to be paid by the buyer

- Wooden Package

- Uttarakhand, Dadra and Nagar Haveli, Lakshadweep, Goa, Maharashtra, Telangana, Punjab, Jharkhand, Arunachal Pradesh, Madhya Pradesh, Himachal Pradesh, Sikkim, Mizoram, Meghalaya, Daman and Diu, Andaman and Nicobar Islands, Karnataka, Manipur, Jammu and Kashmir, Nagaland, Tripura, Pondicherry, Rajasthan, Tamil Nadu, Assam, Haryana, Chandigarh, West Bengal, Bihar, Delhi, Uttar Pradesh, Gujarat, South India, North India, East India, Andhra Pradesh, Kerala, Central India, Odisha, West India, Chhattisgarh, All India

- ISO 9001:2015

Product Description

Backed with technologically advanced manufacturing facilities, we are specialized in manufacturing and exporting Partial Discharge Test Set Up. This testing set is of great use in industries for various testing applications. We strictly follow all the guidelines while manufacturing this Partial Discharge Test Set Up. Our clients can get this testing equipment from us in different models and technical specifications as per their requirements. We offer this equipment to clients at competitive price.

Features:

- Energy efficient

- Low maintenance cost

- Accuracy in results

Specification:

- Input : 230V (<=10 KVA), 415V (>10 KVA) , 50 / 60 Hz, 1

- AC Output : 0 to Max.

- Rated O/P Voltage Capacity : 2KV to 500KV AC ( from several VA to hundreds of KVA ).

- Duty : Intermittent ( 5min. ON,10min. OFF ).

- Other at extra cost Type : Manual, Motor Operated, Fully Automatic.

Precision Testing for Electrical Safety

This Partial Discharge Test Set Up provides accurate assessment of insulation performance in high-voltage equipment. By early detection of partial discharges, users can prevent failures and extend the lifespan of critical machinery. The equipment is suitable for routine condition monitoring in substations, power plants, and industrial facilities.

Reliable and User-Friendly Operation

Designed with the end-user in mind, this test set is easy to operate, featuring clear measurement readings and robust safety measures. The frequency range of 50-60 Hz ensures compatibility with standard electrical systems, making it suitable for diverse testing environments across industrial sectors.

FAQs of Partial Discharge Test Set Up:

Q: How is the Partial Discharge Test Set Up used in practice?

A: The set up is used to monitor, detect, and measure partial discharges in insulating systems of electrical equipment by applying voltage and recording discharge levels, helping prevent insulation breakdown.Q: What benefits does this test system offer to manufacturers and suppliers?

A: By enabling early identification of insulation defects, the system minimizes risks of equipment failure, enhances safety, and reduces costly maintenance or unexpected downtime.Q: When should a Partial Discharge Test be conducted?

A: It is recommended to conduct partial discharge testing during the commissioning phase, scheduled maintenance intervals, or whenever insulation integrity is in question, to ensure safe operation.Q: Where can this test set up be used?

A: The test set is suitable for use in power plants, substations, manufacturing plants, and any environment where high-voltage equipment and insulation systems require regular monitoring and diagnostics.Q: What is the process involved in a Partial Discharge Test?

A: The process generally involves connecting the test set to the equipment under inspection, applying the appropriate voltage, and capturing discharge signals for analysis, which helps pinpoint insulation weaknesses.Q: What warranty does this product include?

A: This Partial Discharge Test Set Up comes with a 12-month warranty, ensuring product reliability and peace of mind for users.Q: How does the frequency specification (50-60 Hz) impact usage?

A: The frequency range ensures the test set is compatible with standard power systems in industrial and utility sectors, providing flexibility for varied electrical environments.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Bushing And Surge Arrestor Insulator Testing Sets' category

Works:

117, Mishrapara Road, Rathtala, P.O. Rajpur,

Kolkata - 700 149, West Bengal, India.